Wire Diameter 3-6mm Mesh Width 2.5m Welded Wire Mesh Panel Welding

Machine

Welded Wire Mesh Panel Welding Machine Introduction:

1. Control System

The control system adopts synchronous control technique. The

welding time and separate welding are controlled by computer with

PLC program touch screen system and HMI.

2. Mesh Pulling Part

The mesh pulling system controlled by servo-motor adopts elastic

tension and opening positioning mesh, which improves the precision

of mesh opening size.

3. Line wire sending part

The mesh sending system is controlled by computer. It simplifies

the process that every tensile spring has to be changed when the

wire diameter is different. You only need to change the pressure of

welding point. Welding aperture can adjust randomly within range.

4. Wire Feed Way

The line wires and cross wires should be pre-straightened and

pre-cut.

The line wire is feeding by the servo motor, pulling the mesh the

servo motor auto. The cross wires are fed automatically from the

multi hopper which capacity is more over ten times than the

traditional hopper.

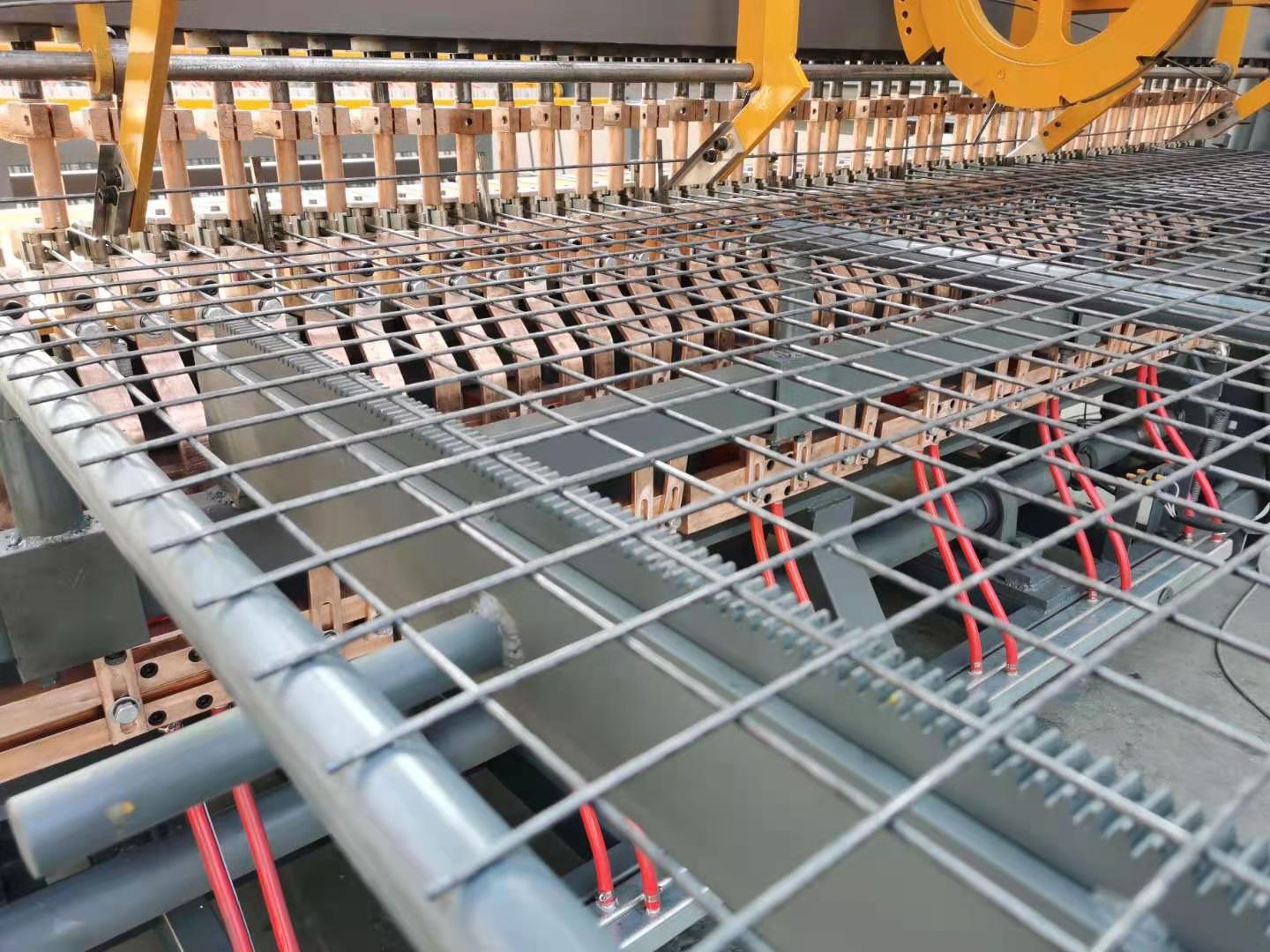

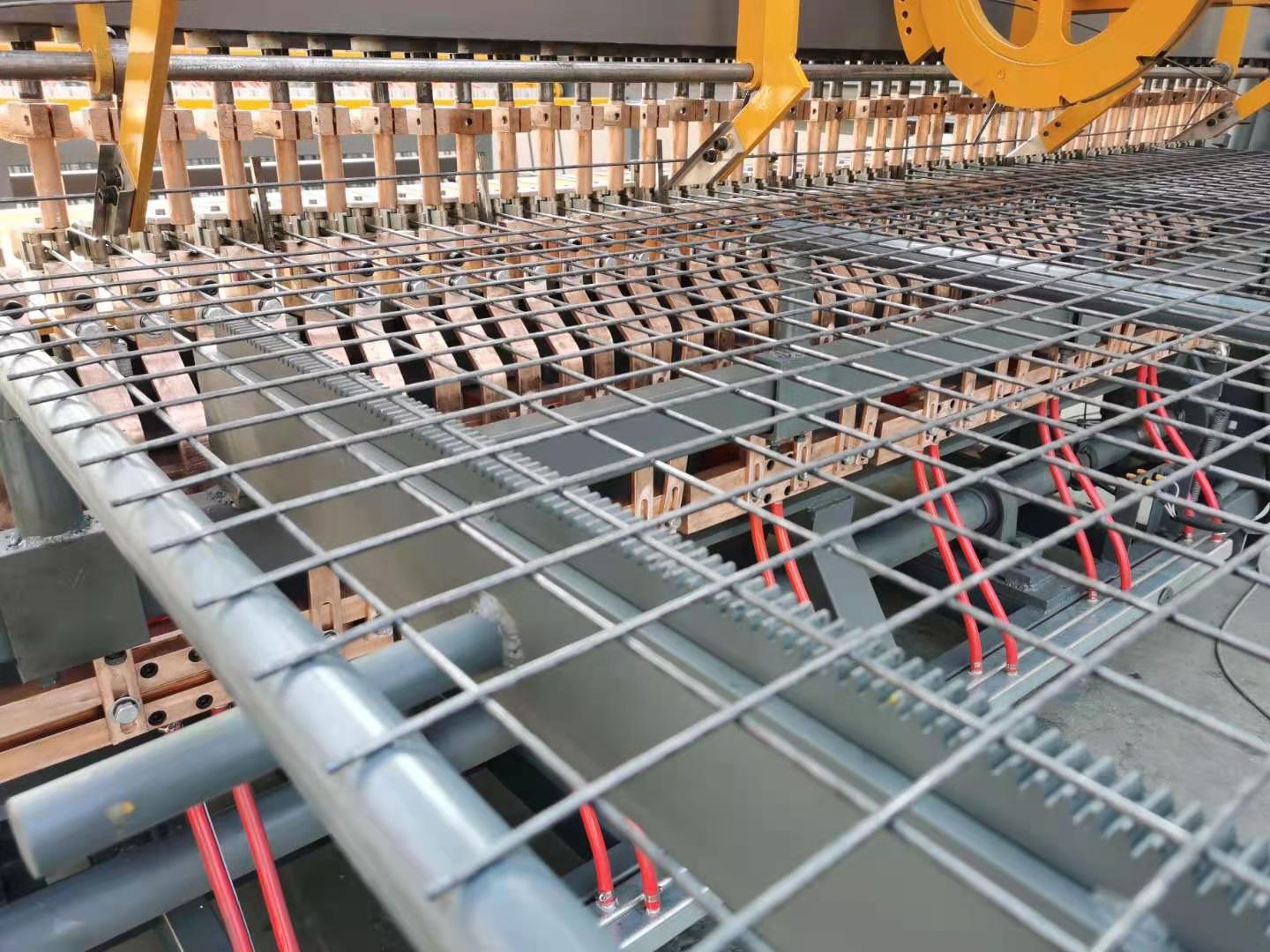

5. Welding Electrode

There are 48 pieces of electrodes that are special-designed and are

made of square column copper. They show little wear rate and can be

used on multiple sides.

6. Welding transformer

This machine equips 6 pieces of typical and efficient transformer,

which has 8 grades, enlarging the welding wire diameter range.

Every two welding electrodes need a water cooling transformer.

Welded Wire Mesh Panel Welding Machine Features:

1. Control system:Japan Panasonic intelligent PLC

2. Touch screen: Weiview(Taiwan).

3. Low-voltage apparatus :Schneider(France). Variable-frequency

drive:Delta(Taiwan)

4. Brake clutch motor connect the pricipal axis directely, stronger

power.

5. Cross wire feeding: Step hopper. Longitude wire

feeding:Manually(or equipted with a wire feeding car).

6. Mesh pulling:Panasonic(Japan) servo motor,great power and

precision.

7. Transformer cooling:Water cooling. Electrodes cooling: Water

cooling, very efficient.

Welded Wire Mesh Panel Welding Machine Technical Parameters:

| Model | DX-GWC-2500D | Wire diameter | 3mm-6mm |

| Longitude wire space | 50mm-300mm | Cross wire space | 50mm-300mm |

| Mesh width | Max.2.5m | Longitude wire feeding | Pre-straightened &pre-cut |

| Welding speed | 45-65times/min | Cross wire feeding | Pre-straightened &pre-cut |

| Welding electrodes | 48pcs | Rated electrical power | 125kva*6pcs |

| Machine size | 7.5M*3.2M*1.7M | Weight | 4.5T |

Welded Wire Mesh Panel Welding Machine Applications:

It is widely used in industry and construction, such as building

board, the roof, the wall, the bridge, concrete road, the floor,

the airport, cement pipe, concrete prefabricated components,

retaining wall, protection slope, the tunnel, the dock, the dyke,

construction reinforcing mesh; highway; railway; bridge; enclosure

mesh; fencing and so on.

Welded Wire Mesh Panel Welding Machine Photos: